Start Your Own Etsy Shop with Unique 3D Printed Coasters!

Are you spending too much time looking for products?

- App rating

- 4.9

- Trending Product

- 2M+

- Trusted Customers

- 1000+

WHY YOU SHOULD CHOOSE Etsyshop

WHY YOU SHOULD CHOOSE Etsyshop

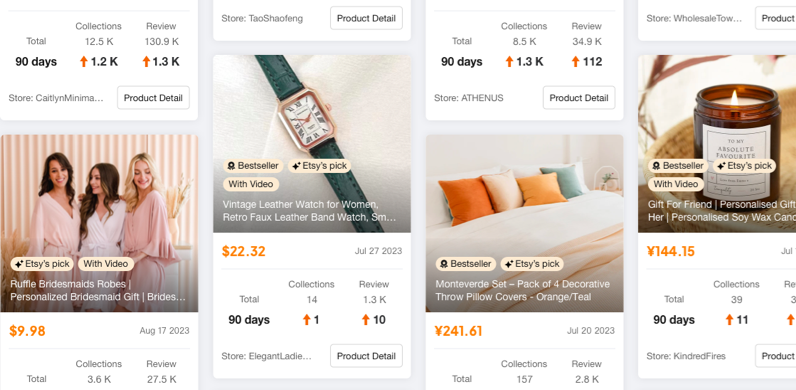

Etsyshop has the world's largest selection of ETSY store to choose from, and each product has a large number of ETSY products, so you can choose ETSY store & product for your Ecommerce and dropshipping business without any hassle.

Browse More Content

Etsy shop

- Discover Untapped Print on Demand Products with ChatGPT4

- Unleashing Etsy's Unstoppable Growth

- Profitable Hand Towel Embroidery: Etsy Selling Guide!

- New Holiday Cards and Author Portraits on Etsy!

- ETSY STAR SELLER Secrets Revealed

- Exciting Update: My First Plushie Arrived! - Business Vlog

- Unbridled Etsy Battles: KingCobraJFS vs the World

- Unboxing Beautiful Orchids from Etsy's Triton Orchids

- Empowering Women in Tech: Etsy's Remarkable 500% Growth in Female Engineers

- Maximizing Profit: Etsy vs Poshmark

Etsy Seller

- Unveiling the Dark Secret of the Etsy Algorithm

- Level up your style with trendy sleeve prints from Etsy + Printify

- Etsy Prep: Best Pricing Tips for Plushie Drop 2023

- Making Passive Income with Digital Scrapbook Elements

- Easily Adding Videos to Etsy Listings Using an iPhone

- Create & Sell Digital Downloads on Etsy with Canva

- Unveiling the Dark Side of Etsy: #KeepEtsyHuman

- Skyrocket Your Etsy Sales with This TikTok Hack

- Earn $3000/mo with Etsy Selling Squarespace Templates

- Create and Sell Digital Paper for Etsy

Etsy Seo

- Unlocking Etsy Success with Google SGE

- Mastering E-Commerce SEO: Your Path to Success

- Unveiling Etsy's SEO Changes in 2023

- Boost Your Etsy SEO: Common Mistakes to Avoid

- Unlock Etsy Success: Strategies for Finding Unsaturated Niches

- Mastering SEO Writing for Online Success

- Mastering Etsy SEO: Boost Sales & Visibility

- Unlock Etsy SEO 2023: Top Digital Products & Keywords

- Maximizing Marmalade for Etsy SEO Success

- Boost Your Etsy SEO in 2023

Etsy Dropshipping

- Master the Art of Selling Posters on Etsy

- Dropshipping Success: $31,271 in 1 Month!

- Streamline Multi-Channel Sales with Nimble Web

- How I Made $45k in 2 Months on Etsy - A Case Study

- The Ultimate Guide to Succeed in Etsy Drop Shipping

- Etsy vs. Shopify: Crafting Your E-Commerce Success

- Etsy vs Shopify: Which Platform is Right for You?

- Dominate the Wedding Jewelry and Accessories Market on Etsy

- Etsy vs Shopify: Making the Right Choice for Your Online Business

- Etsy vs. Shopify: Choose Your E-commerce Path