Inside Look: Behind the Scenes of a Soap Shop

Table of Contents

- Introduction

- Setting Up the Soap Shop

- Custom Soap Shelf

- Dehumidifier for Faster Drying

- Soap-making Process

- Curing Soaps

- Shaving and Labeling

- Soap Recipes and Customization

- Designing Labels

- Printing Labels

- Using Canva for Design

- Label Printing Services

- Packaging and Storing Soaps

- Minimal Packaging

- Storage Solutions

- Online Selling on Etsy

- Incorporating Shipping Costs

- Promotions and Discounts

- Wholesale and Local Sales

- Startup Expenses and Overhead

- Future Plans and Monetization

Behind the Scenes: Running a Tiny Basement Soap Shop

Introduction

Hey there! I'm Rachel, and I'm excited to share the behind-the-scenes details of how I run my small soap business from the comfort of my tiny basement. Over time, I've perfected my system through experiments and extensive research. In this article, I'll be sharing tips and tricks that can be beneficial to anyone looking to start their own soap shop. Whether you're just getting started or already have some experience, I hope you find these insights valuable.

Setting Up the Soap Shop

Custom Soap Shelf

One of the essential elements of my soap shop is a custom soap shelf that my loving husband made for me. This shelf fits perfectly on our basement wall, making use of previously wasted space. It serves as an excellent display for my soaps and even doubles as a backdrop for my videos. The bottom shelf, specifically designed to withstand the weight, is dedicated to housing the soy candles I sell on my Etsy shop.

Dehumidifier for Faster Drying

To expedite the drying process, I rely on a basic dehumidifier I purchased from Walmart. This dehumidifier, although simple, effectively helps dry out the soaps faster. Since the goal of curing soaps is to remove as much water as possible, a dehumidifier becomes a valuable tool in ensuring the production of long-lasting bars. An adequately cured soap lasts longer, especially when it comes in contact with water.

Soap-making Process

Curing Soaps

I usually let my soaps cure for a minimum of five weeks. Curing allows for the removal of excess water, resulting in harder bars that last longer. During this curing period, I make use of a reliable dehumidifier to speed up the process. The buzzing noise you might hear in the background of my videos is the dehumidifier doing its job.

Shaving and Labeling

Once the soaps are fully cured, I move on to the next step, which involves shaving and labeling. While some soap makers prefer leaving their soaps rough cut for a faster process, I personally prefer the clean and finished look. To achieve this, I clean up the edges using a vegetable peeler. Afterward, I weigh each bar using a kitchen scale, ensuring consistency across the batch. Labeling plays a crucial role in my soap-making process, as it provides essential details for customers. I write down the recipe, ingredients, date of creation, and any additional information on a note card for reference.

Soap Recipes and Customization

Unlike larger soap companies that often use the same recipe across all their products, I enjoy experimenting with various soap recipes. Different ingredients naturally lend themselves to specific bars. While it might take extra time, customizing the ingredients for each soap adds a personal touch and allows for greater creativity. I keep a record of my recipes in a notebook, including the ingredients, percentages, and date of creation, for future reference and label creation.

Designing Labels

When it comes to designing labels, I rely on a graphic design tool called Canva. With a professional account, I have access to a wide range of features that make label creation a breeze. Canva has become an indispensable tool for various aspects of my business, from creating coloring sheets for my kids to making flyers and signs for events. I've created a template for my soap product labels, allowing me to update the information easily for each batch. This feature has significantly sped up the labeling process and ensures consistency throughout my product line.

Printing Labels

After designing the labels in Canva, I download the images and print them using an online label printing service called OnlineLabels.com. They offer a good selection of colors and sizes, and their prices are reasonable. For soaps and candles, I use two-inch brown craft paper labels. Inside my shipping and gift boxes, I use two and a quarter-inch brown craft paper labels for branding purposes. Additionally, for the outside of my packaging, I opt for two and a quarter-inch waterproof labels. Lip balm tubes require clear waterproof labels, allowing customers to see the product and gauge how much is left.

Packaging and Storing Soaps

Minimal Packaging

I prefer keeping my packaging minimal to allow customers to engage with the soap. I typically use a simple technique called "belly banding," where I cut one and a half-inch strips of brown craft paper and wrap them around the soap like a band. This approach allows customers to touch, feel, and smell the soap closely. It also makes it easy to slide the band up or down to reveal the soap. I primarily reserve shrink-wrapping for soaps with delicate components, ensuring protection during shipping.

Storage Solutions

To maintain the quality of my soaps, I use shoe boxes on a shelf in my utility room. These shoe boxes offer individual compartments, preventing different scents from blending with one another. I create labels for each box, noting the soap title and production date. This system allows me to keep track of inventory, scratching out the sold units and updating the available quantities regularly. The transparent window on these shoe boxes provides a convenient way to glance at the stock levels.

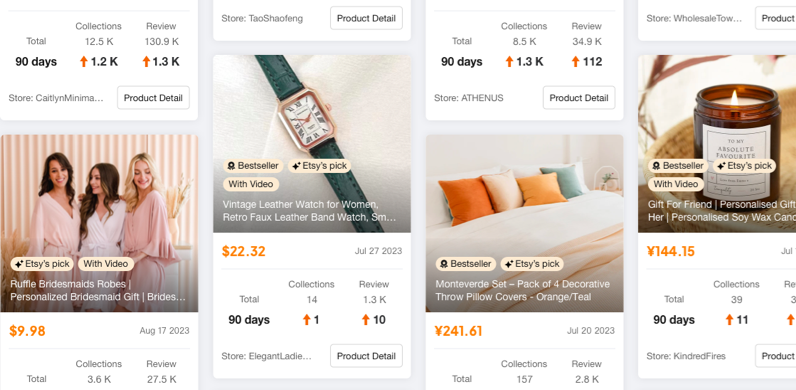

Online Selling on Etsy

Etsy serves as my primary online selling platform. While they do take a small percentage of each sale, along with a listing fee, they provide a user-friendly website that helps reach a broader customer base. Incorporating shipping costs into the product's price is crucial to make shipping discounts or even free shipping feasible, as shipping charges can be quite expensive. By incentivizing customers to purchase more, I aim to offset the shipping costs and encourage them to take advantage of promotions or free shipping for higher orders. Etsy's website navigation is relatively straightforward, making it easy to manage listings and transactions.

Wholesale and Local Sales

In addition to online selling, I also cater to wholesale customers and participate in local farmers markets and craft shows. While selling directly to customers allows for personal interaction and showcasing the products, wholesaling provides the opportunity to reach a wider audience. Establishing relationships with local retailers and attending craft shows helps expand my customer base and generate more sales.

Startup Expenses and Overhead

Starting a soap business involves various overhead and startup expenses. These include marketing materials, soap-making supplies, storage solutions, labeling, shipping, and even business insurance. Joining a craft guild or a professional organization specific to handcrafted soap and cosmetics is essential to protect yourself legally and financially. While these additional expenses may impact the bottom line, they are crucial for operating a successful and sustainable business.

Future Plans and Monetization

As a small soap business owner, I have learned the importance of prioritizing and focusing on growth. Currently, I primarily rely on my YouTube channel and Instagram account to market my products and drive traffic to my Etsy shop. Monetizing my YouTube channel serves as a long-term goal, enabling me to generate a steady income while allowing me to spend quality time with my family. As my soap business expands, I plan to consider creating my own website and domain to provide a more comprehensive online presence.

Highlights

- Setting up a custom soap shelf in the basement provides an efficient and attractive way to display soaps.

- Using a dehumidifier accelerates the soap drying process and ensures harder bars with longer lifespans.

- Curing soaps for at least five weeks improves their quality and durability.

- Shaving and labeling soaps create a professional finish, with proper weighing and labeling for tracking and marketing purposes.

- Designing labels using Canva simplifies the process and allows for customization.

- Online label printing services, such as OnlineLabels.com, offer convenience and professional results.

- Minimal packaging, such as belly banding, enhances the customer experience while still protecting the soap.

- Selling on Etsy provides access to a wide customer base, but shipping costs must be factored into pricing strategies.

- Exploring wholesale opportunities and participating in local markets and shows expand the reach of the soap business.

- Managing startup expenses and overhead ensures the financial sustainability of the soap business.

- Future plans may involve monetizing through YouTube and creating a dedicated website for the soap business.

WHY YOU SHOULD CHOOSE Etsyshop

WHY YOU SHOULD CHOOSE Etsyshop