Incredible Robot Sewing Machine Helps Etsy Seller

Table of Contents

- Introduction

- Computer-Guided Sewing Machines

- Benefits of Making Products In-House

- The Versatility of Computer-Guided Sewing Machines

- Creating Templates and Programming the Machine

- The Importance of Automation

- Making the Pattern and Cutting the Leather

- Assembling the Template

- Programming the Stitch Pattern

- Testing and Adjusting the Template

- Calculating Production Costs

- Comparing to China's Pricing

- Flexibility and Market Adaptability

- Opening an Etsy Shop

- Conclusion

Computer-Guided Sewing Machines: Revolutionizing Product Manufacturing

When it comes to manufacturing products, efficiency and cost-effectiveness are crucial factors. In recent years, computer-guided sewing machines have emerged as a game-changer in the industry. These machines offer a wide range of capabilities, from creating wallets and keychains to Holister straps and camera bag accessories. In this article, we will explore the world of computer-guided sewing machines and their role in streamlining the production process. We will delve into the benefits of making products in-house, the endless possibilities offered by these machines, and the steps involved in creating templates and programming them. Additionally, we will discuss the importance of automation in achieving cost savings and the significance of market adaptability in the face of competition from larger manufacturers, such as China. So, let's dive in and discover how computer-guided sewing machines are revolutionizing the way we create products.

Introduction

In today's rapidly changing landscape of manufacturing, it has become essential for businesses to find innovative ways of producing goods. One such innovation is the advent of computer-guided sewing machines. These machines, with their advanced programming capabilities, have opened up a world of possibilities for small businesses and entrepreneurs. Gone are the days when manufacturing was limited to large factories and offshore production. With computer-guided sewing machines, it is now possible to create high-quality products in-house, offering greater control over costs and customization. In this article, we will explore the various aspects of computer-guided sewing machines and how they are reshaping the manufacturing industry.

Computer-Guided Sewing Machines: A Game-Changer in Manufacturing

Computer-guided sewing machines have become a valuable tool for businesses looking to streamline their manufacturing processes. These machines utilize advanced technology to automate stitching patterns, allowing for precise and consistent results. From wallets and keychains to Holister straps and camera bag accessories, these machines can be programmed to create a wide range of products. With the ability to design and modify templates, businesses can cater to various customer demands without the need for outsourcing or relying on external suppliers. This level of flexibility offers a significant advantage over traditional manufacturing methods.

The Benefits of In-House Production

One of the primary advantages of using computer-guided sewing machines for in-house production is cost savings. By eliminating the need for outsourcing or purchasing ready-made products from overseas suppliers, businesses can significantly reduce their manufacturing expenses. This cost reduction is particularly relevant in today's market, where shipping prices are often unpredictable, making offshore production less financially viable. Moreover, by producing products in-house, businesses have better control over the quality of their goods, ensuring that every item meets their specific standards. This level of quality control is crucial for maintaining customer satisfaction and building a strong brand reputation.

The Endless Possibilities of Computer-Guided Sewing Machines

The versatility of computer-guided sewing machines is truly remarkable. Imagine having the ability to create intricate designs or stitch patterns with just a few clicks of a button. These machines allow businesses to unleash their creativity and experiment with different materials, patterns, and sizes. Whether it's a bottle opener, a dog collar, or a unique accessory, the possibilities are virtually endless. With the ability to program stitch patterns, businesses can quickly adapt to new trends and customer preferences. This adaptability is essential in a market where consumer tastes are constantly changing.

Creating Templates and Programming the Machine

To utilize the full potential of computer-guided sewing machines, businesses must create templates and program the machine accordingly. Templates act as guides for the machine, ensuring precise stitching and accurate product dimensions. Creating templates involves designing and cutting materials, such as wood or acrylic, to fit the machine's specifications. Using a CO2 laser machine, businesses can create precise templates that can be replicated effortlessly. Furthermore, businesses can communicate with the machine manufacturer to tailor the template precisely to their needs. This level of customization enables businesses to fine-tune their production process and achieve optimal results.

The Importance of Automation in Manufacturing

Automation plays a crucial role in achieving cost savings and maximizing efficiency in manufacturing. With computer-guided sewing machines, businesses can automate various tasks that would otherwise be performed manually. This automation reduces labor costs and minimizes the risk of human error. Additionally, automated stitching patterns ensure consistent and uniform results, enhancing the overall quality of the end product. By embracing automation, businesses can improve their productivity and competitiveness in the market.

Making the Pattern and Cutting the Leather

Once the template is ready, the next step is to create the pattern for the specific product. In the case of a bottle opener, businesses need to cut leather precisely and stitch it onto the metal piece. Using scissors or laser machines, the leather is cut according to the desired pattern. This precision ensures a snug fit and enhances the overall appearance of the product. By leveraging the capabilities of computer-guided sewing machines, businesses can create patterns effortlessly and replicate them as needed.

Assembling the Template

After cutting the leather, businesses assemble the template by attaching the cut leather piece to the pre-designed template. Using adhesive, such as super glue, businesses secure the leather onto the template, ensuring a secure fit. This assembly process is critical to maintaining the integrity and functionality of the template. Furthermore, businesses can experiment with different materials, such as wood or acrylic, to enhance the durability and longevity of the template.

Programming the Stitch Pattern

Before commencing the sewing process, businesses must program the stitch pattern into the computer-guided sewing machine. This involves attaching the bottle opener securely and mapping out the desired stitch path. By tightly guiding the sewing needle along the bottle opener, businesses can achieve precise and professional stitching. Programming the stitch pattern can be time-consuming, as it requires careful adjustments and testing. However, with patience and practice, businesses can perfect their stitch patterns and create high-quality products consistently.

Testing and Adjusting the Template

Once the sewing pattern is programmed, businesses can proceed with the first sewing attempt. This initial sewing test allows businesses to evaluate the results and make any necessary adjustments. In the case of the bottle opener, businesses assess the fit and the tightness of the stitch. If changes are required, adjustments can be made to the template or the stitching pattern to ensure a seamless result. Testing and adjusting the template are crucial steps in achieving optimum product quality.

Calculating Production Costs

To determine the cost-effectiveness of in-house production, businesses must calculate their production costs accurately. This involves considering the cost of materials, labor, and any additional expenses associated with the manufacturing process. By comparing these costs to the prices offered by suppliers, such as China, businesses can assess the financial viability of producing their own goods. However, it is essential to consider additional factors, such as shipping costs, when making a final comparison. Only through a comprehensive analysis can businesses make informed decisions regarding their manufacturing strategies.

Comparing to China's Pricing

China has long been known as a manufacturing powerhouse, offering products at competitive prices. While in-house production may not always offer cost savings when compared directly to China's pricing, other advantages come into play. By producing goods in-house, businesses gain greater flexibility in terms of product variations and customization. They can cater to specific market demands without having to commit to bulk orders. This adaptability enables businesses to stay agile and responsive to customer preferences, giving them a competitive edge.

Flexibility and Market Adaptability

The ability to adapt to market demands is crucial in a rapidly changing business environment. Utilizing computer-guided sewing machines allows businesses to be flexible and responsive to emerging trends. By monitoring sales and customer feedback, businesses can adjust their production strategies accordingly. They can introduce new product variations or discontinue those that are not performing well. Computer-guided sewing machines enable businesses to experiment, innovate, and stay ahead of the competition.

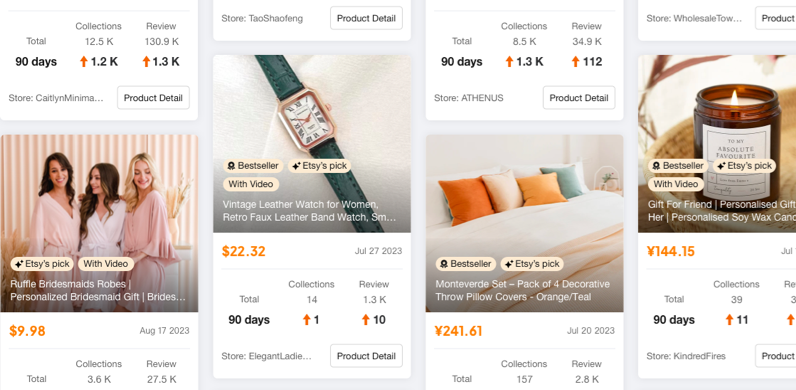

Opening an Etsy Shop

To leverage the potential of computer-guided sewing machines fully, many businesses choose to open an Etsy shop. Etsy provides a platform for artisans, creators, and manufacturers to sell their unique products. By showcasing their handmade, personalized items, businesses can tap into a vast customer base. Opening an Etsy shop allows businesses to reach a broader audience and establish a strong online presence. By documenting their journey and sharing their Etsy shop experience, businesses can inspire and guide others who wish to embark on a similar path.

Conclusion

Computer-guided sewing machines have revolutionized the manufacturing industry, enabling businesses to create high-quality products in-house. By leveraging advanced technology, businesses can automate stitching patterns, improve production efficiency, and reduce costs. The flexibility offered by these machines allows businesses to adapt to changing market demands and stay competitive. While in-house production may not always offer immediate cost savings when compared to outsourced manufacturing, the benefits of customization, market responsiveness, and brand control make it an attractive option. With the right tools and strategies, businesses can harness the power of computer-guided sewing machines and thrive in the ever-evolving marketplace.